Automatic 500-6000kg/h B2B Food Grade Cleaning System in Plastic Recycling Line

Advertised on 15/10/2025

AED 30,000Location:

China - Beijing

Unit:

Set

Price:

AED 30,000

Condition:

New

100 left in stock

Funtion of Food Safe Plastic Recycling Equipment

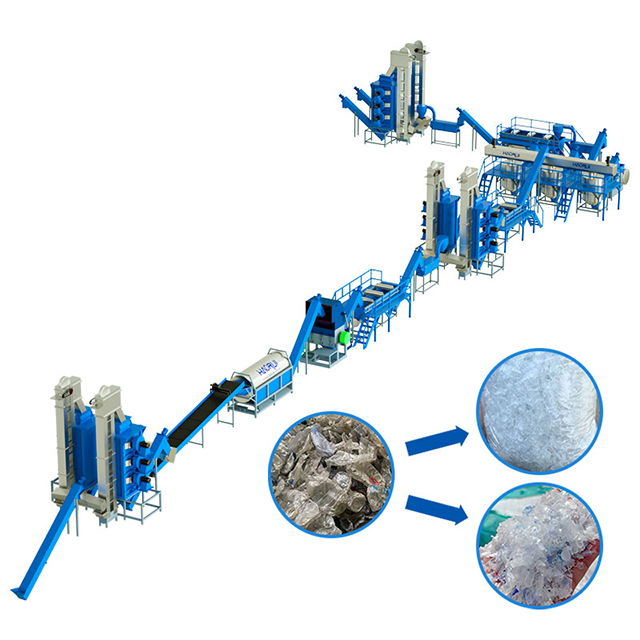

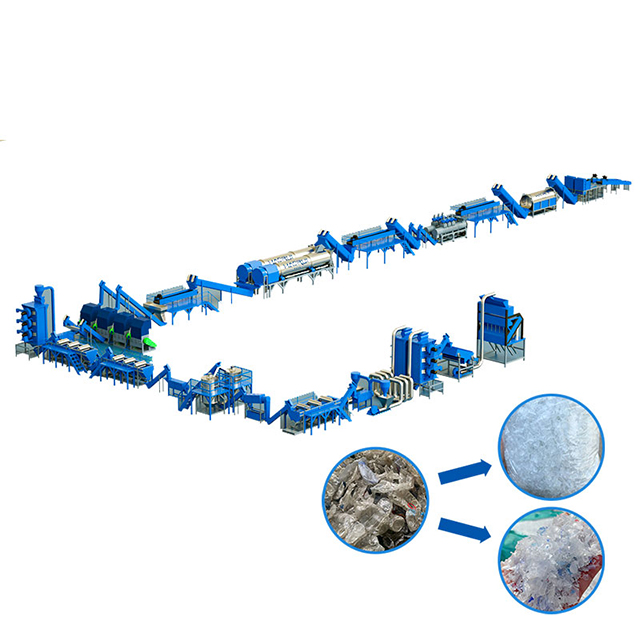

A food grade B2B PET bottle washing recycling line is specialized in transforming post consumer PET bottles into a purified material suitable for making new food-contact items by decontaminating it through a multiple stages process components.

Equipments of Food Safe Plastic Recycling Equipment

The PET bottle washing recycling line is composed of a series of interconnected machine and equipment,including pre-washing,trommel screen,plastic crusher machine,screw,PET bottles label remover machine,floating tank,high speed friction washing,dewatering machine to produce high quality PET flakes,enabling it to run automatically,promoting work efficiency and producticity,saving labor,and minimizing down time.

Addition of Food Safe Plastic Recycling Equipment

This food grade B2B PET bottle washing line adds one set trommel screen to sort the material fast and correctly,one set bottle pre-washing System to remove most external impurities such as sand,stone and even mud on the bottles and most of the sediment and other impurities effectively and one set flakes color&polymer sorter to sort the pet flakes by different colors automatically,and separates non-PET materials,Such as PVC,PC,PP,PE,PA,PLA,PS$,ABS,rubber,etc from the processed materials.

Process of Food Safe Plastic Recycling Equipment

This food safe B2B recycling machine handles a series of multiple stages highly automated of process components to to ensure consistency and reduce human error,making it possible to meet strict food safety standards,invovling de-baling,sorting,pre-washing,crushing,hot washing,friction washing,rinsing and drying to manufacture new food-contact items.

Features of Food Safe Plastic Recycling Equipment

Our food grade B2B PET bottle recycling machine features advanced sorting,multi-stage washing systems,and high-temperature or vacuum purification processes to ensure the output meets food-grade standards,automated sorting with sensors to separate plastics by type,efficient shredders to produce uniform flakes,and sophisticated filtration to remove contaminants, as well as energy-saving and in-line controls to maintain quality throughout the process.

Advantages of Food Safe Plastic Recycling Equipment

Above food safe B2B recycling machine offers numerous advantages,invovling achieving high purity levels and efficiency,enhanced environmental sustainability by reducing landfill waste,cost-effectiveness through reduced virgin plastic use,and improved brand image.

Usages of Food Safe Plastic Recycling Equipment

The B2B food grade cleaning system is used in reprocessing new,food-grade plastics for food packaging like bottles,trays,and other containers,ensuring the recycled materials is clean and safe for food contact.

Automatic 500-6000kg/h Food Grade PET Scrap Bottle Washing Plant:https://www.petrecyclingmachinery.com/Automatic-500-6000kg-h-Food-Grade-PET-Scrap-Bottle-Washing-Plant-pd543106248.html

Plastic Recycling Machines & Solutions - Haorui Machinery:https://www.petrecyclingmachinery.com/

Similar Products

-

Premium

12 Months • 7 days notice period

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

-

Professional

12 Months • 7 days notice period

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

-

Professional

12 Months • 7 days notice period

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

XXL pictures & videos

UAE - Dubai

User since:

18/09/2025

UAE - Dubai

User since:

18/09/2025

Add to favorites

Add to favorites